Home • 2019–2020 • 2018 • 2017 • 2016 • 2015 • 2014 • 2013 • 2012 • 2011 • 2010 • Prior Years

Photographs and drawings by Georgette Freeman © 2012. All rights reserved.

Copyright © 2012 by Georgette Freeman. All rights reserved.

2 0 1 2

Currently on the Drawing Board: 11/2012

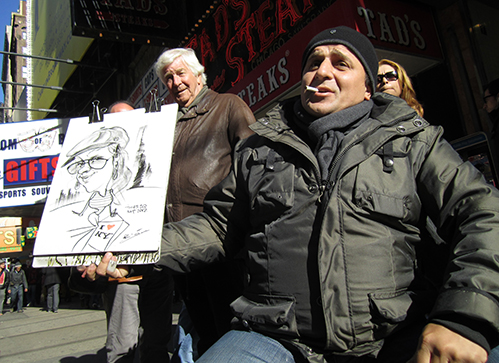

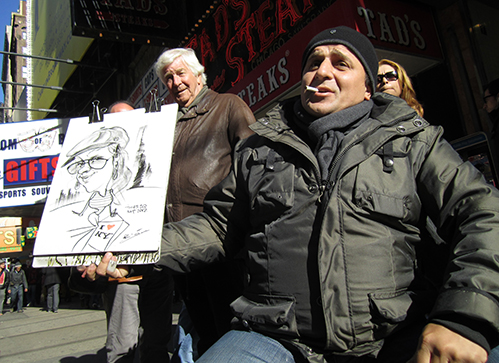

NYC: North side of Times Square on Broadway, the Sunday after Sandy. Caricature is of me. I'm seated in front of the street artist in his "subject" chair.

Currently on the Drawing Board: 10/2012

Currently on the Drawing Board: 09/2012

Currently on the Drawing Board: 08/2012

For Bone Batch 1, the whole process was very satisfying. From separating the hooves from 8 elk lower leg bones to cleaning up the cooked bone. The ankle bones of 5 had separated from the leg bones and 3 had not.

The lower leg bone structure was very clear by the finish. Looking from the ankle end, the structure is triangular and should be easily resolved with a well-tuned band saw. Looks like three length-wise cuts at the interstices of the ankle end structure, from one end to the other, should do it.

Each of the 5 bones without the ankle is approximately 11.75 inches long. Wet, the eight bones weighed from 12–13 ounces (5), to 14 ounces (2), and 16 ounces (1). (The three bones weighing more than 13 ounces had retained their respective ankle bones.)

Monday 8/27, I intend to section one bone with the band saw, the driest of the bunch (the bone having been dried in the oven heated by the pilot lights) and, with cutting, I will resolve its lengthwise triangular structure. From this I should have a good idea of the bone marrow distribution and the depth of bone around the marrow socket. (The leg being dried is #1 which weighed 12.5 ounces (wet) and, lacking an ankle, is 11.75 inches long.)

In terms of time, now with proper equipment and procedures: a 32 quart/8 gallon pot (13.5 inches wide, 14 inches high) and more efficient butchering (elk hoof removal in <5 minutes), I should be able to process elk bones at the rate of about 7 minutes each, which means 1.5 hours prep for the next batch of 16 bones, and a total cooking time of about 10 hours. (Assuming the pot is set to boil at the outset of the de-hooving procedure).

Timing will be critical for Bone Batch 3. Coming 2nd-Day- Air/FedEx, I'll have the late afternoon and evening to process, cook, cleanup, and set 12 elk bones and at least 1 buffalo leg bone out for drying, before departing early the next day for Bandon OR, which is 9 driving hours and 465 miles of travel.

Early the following morning, 9/21, I'm expected at Sas Colby's Bandon workshop at Sage. Over the remaining 2–3 days after Sas's workshop, I intend to work some bone at a campsite about two miles north of Bandon.

Currently on the Drawing Board: 06/2012

Just like clock-work, another lazy summer beckons. Have visions of idyllic camp fires on which I am boiling elk bones in a tub set over the fire (upper leg bone, possibly the larger of the two lower leg bones, scapulas, and flat breast bones: no horn, ever), or hours spent around a small fire in a populated beach-side campsite, working bone with bone files and sandpaper. (Steel wool fouls worked bone.)

In bone working, my experience is that all the excitement is being the one to make the first cut(s) into whole bone with a band-saw. (Small, precision table mounted band-saws are made for just this kind of work and, what with electricity usually being thrown in with most public camp sites today, the need for a power tool shouldn't get in the way of finding an idyllic setting.)

Here, in those cuts, is where bone is first "shaped" for making into a hand tool. Everything afterwards is finish and I so love coming up with different shapes—bookbinding accommodates a number of them. But, lacking an inventory of good solid, uncut elk bone, I'm feeling the need to find a source, a farmer/butcher perhaps, who will work with me.

Again, there's nothing like having choice leg bones to work on and, what with CODEX 2013 being just 7 months away, I've got to do something. I'm sure a display case of varied, worked bones would be a show-stopper. Anyway, to that end, above are pictured most of what I've worked to date. I want very much to broaden my shapes, but my poor inventory of uncut bone stands in the way.

Though I've occasionally come by game deer bones from slaughterhouses, and one recently dead road-kill on SA's brother's property (yes, I did harvest that deer's legs—one step ahead of vultures, but that's another story), all else I have on hand are sun-bleached deer bones picked up from Eastern Oregon roadways in late spring, 2010 and 2011—not good—the bones are fractured and always over-desiccated.

So, one thing more to do this early summer. I need to find a source of elk bones.

Currently on the Drawing Board: 05/2012

Currently on the Drawing Board: 03/2012

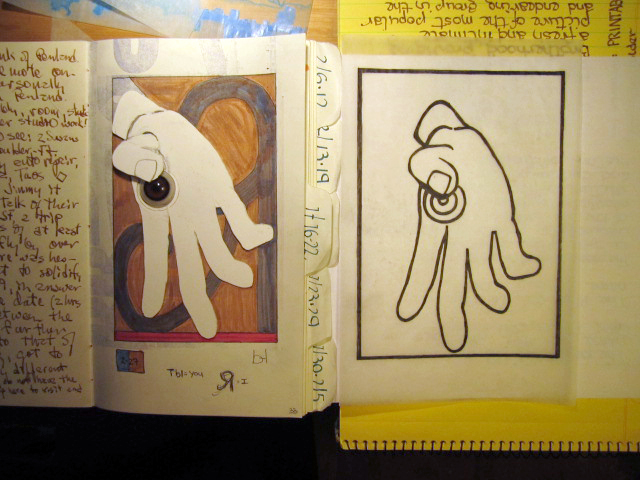

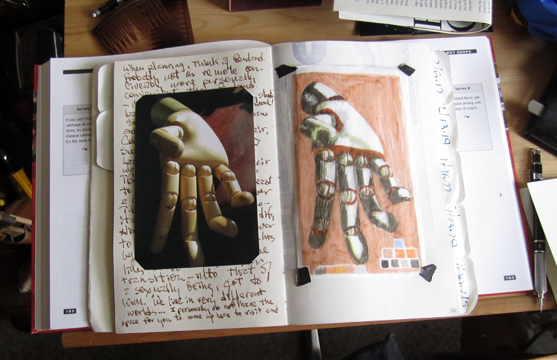

Scheduler U, p. 33, March 4

Currently on the Drawing Board: 02/2012

Scheduler U, pp. 32–33, February 26

Home • 2019–2020 • 2018 • 2017 • 2016 • 2015 • 2014 • 2013 • 2012 • 2011 • 2010 • Prior Years